Description

Precision material cutting – laser beam cutting, water-jet cutting and electrical discharge cutting

Laser beam metal sheet cutting

- Laser beam cutter – BY SPRINT 3015 Bystronic – for the components of the following dimensions: 1500×3000 mm and weight up to 750 kg.

Types of steel materials designated for cutting:

- steel up to 15 mm thick,

- stainless steel and acid-resistant steel up to 8 mm thick,

- aluminum and its alloys up to 6 mm thick,

- brass up to 3 mm thick.

The machine performs engraving on each component, so they are properly labeled.

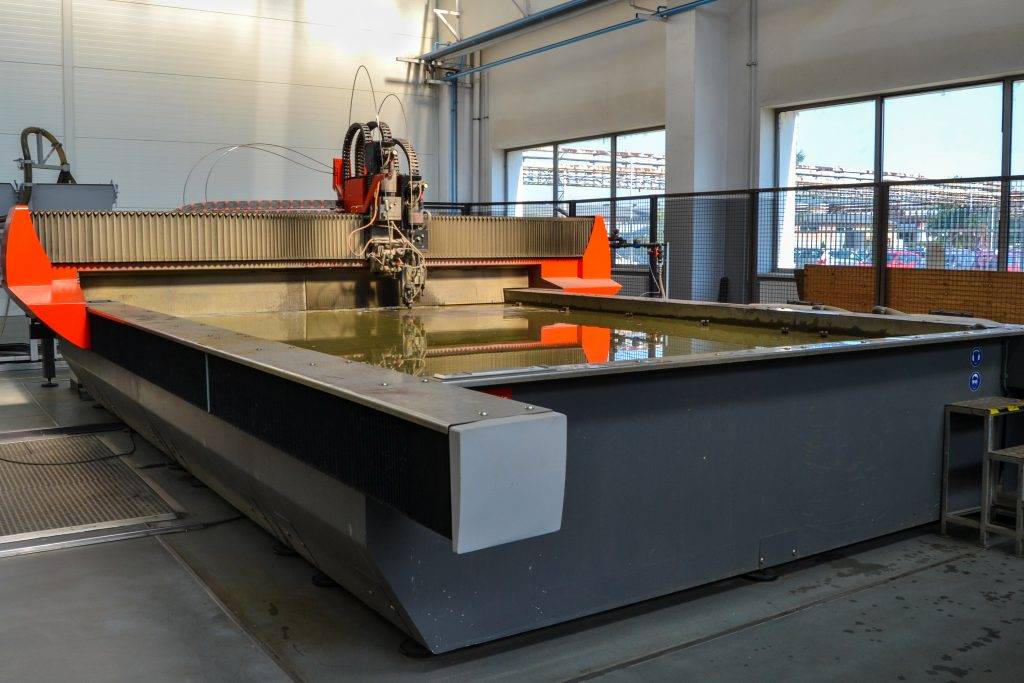

Water-jet cutting

- The brand of water-jet cutter currently in use: Waterjet Bystronic Byjet Flex 6030 – the maximum dimensions of components: 6000×3000 mm, the maximum weight pressuring the table up to 1600 kg per square meter (1600 kg/m²), the maximum component height: 205 mm, placement accuracy: ± 0.05 mm/m, water-jet cutter cuts different types of materials (steel, aluminum, artificial and recycled plastic, granite, marble, glass, ceramic ware, composite material, foams, sponges etc.), the rendered details do not require after-treatment, the replicability average ratio: ±0.025 mm, 2D and 3D cutting, the maximum head turning angle 3D 45°, the machine is adjusted to engraving of components.

Electrical discharge cutting

The brand of wire electric discharge cutter currently in use – MV2400S Tubular Mitsubishi Electric – power cross traverse: X: 600 mm, Y: 400 mm, Z: 310 mm, U and V axis traverse: 150×150 mm, the maximum component dimensions: 1050x820x305 mm, the maximum component weight 1500 kg, table dimensions: 840×560 mm, the maximum cutting angle/height of the component: ±15°/260 mm, ±45°/75 mm, the applied wires have the following parameters: 0.10÷0.30 mm.

Gallery