Description

Plastic working

Metallurgical material cutting

- sheet material cutting with guillotine shear – the maximum cutting length: 2000 mm, the maximum sheet metal thickness: 6 mm,

- pipe cutting, rod cutting, rectangular profile cutting, flat cutting using band-sawing machine – the maximum cross-section dimensions: 270×270 mm or Æ 270 mm, angles range of blade guide arm: 0°÷60°,

- die shearing of metal sheet components – the maximum sheet metal thickness: 3 mm.

Metal material bending

- sheet metal bending using numerically controlled hydraulic bending brake press – tonnage capacity: 100 tonnes – the maximum bending length: Lmax=3000 mm for the maximum sheet metal thickness up to Gmax=2.5 mm (S235JR), the maximum sheet metal thickness:

Gmax=8 mm for the material type S235JR and R bending ~ 1.2 G Lmax [m]= , - sheet metal bending using hydraulic bending brake press controlled numerically – tonnage capacity: 500 tonnes – the maximum bending length: 4000 mm for the maximum sheet metal thickness up to 12 mm (S235JR), the maximum bending length: 3000 mm for the maximum sheet metal thickness up to 15 mm (S235JR),

- sheet metal rolling (metalworking) using 3-cylinder rolling mill – the maximum sheet metal thickness: 3 mm, the maximum bending length: 1000 mm,

- sheet metal stamping (forming) – the maximum sheet metal thickness: 3 mm, the maximum stamping depth: 170 mm, overall dimensions of the expanded sheet metal: 1500×500 mm,

- pipe bending, rod bending rectangular profile bending using numerically controlled 5-axis bending brake press – the maximum detail length: 4000 mm, bent material types:

- round pipes made of soft steel (Rm ≤ 45 kg/mm²) up to 65 mm in diameter, the maximum thickness of the wall: 4 mm,

- round pipes made of stainless steel: the maximum diameter: 60 mm, the maximum thickness of the wall: 3 mm,

- rectangular or square profiles made of soft steel, overall dimensions: 50×50 mm, the maximum thickness of the wall: 2 mm,

- round rods made of soft steel – the maximum diameter: Æ 35 mm,

- square rods made of soft steel in the following dimensions: 30×30 mm.

Flat-die forgings

- round and flat rods, plain and stepped shafts – the maximum forging length: 1500 mm,

the maximum forging diameter: Æ 320 mm, the maximum forging weight: 150 kg, - cubes, disc sheaves and pierced discs – the maximum forging diameter: Æ 400 mm,

the maximum forging weight: 140 kg, - rings and bushings becked with cylindrical mandrel – the maximum forging diameter:

Æ 400 mm, the maximum forging height: 150 mm, the maximum forging weight: 120 kg.

Impression-die forgings

- plain and off-center shafts, lever connecting rods, valve housings, tee and straight elbow housings, cogwheels, integral collars – the maximum forging diameter: Æ 180 mm, the maximum forging length: 300 mm, the maximum forging weight: 0.20÷9.0 kg,

- shaft forgings using single driven cold header – the maximum forging diameter Æ 38 mm.

Applied material grades

- structural carbon steel and alloy steel,

- heat-treatable steel, carburizing steel and nitriding steel,

- stainless steel,

- acid-resistant steel.

Welded structures

- structural steel components spot welding – (max. 0.22%),

- soft and hard soldering,

- steel structures welding according to MAG and TIG methods structural steel components – including stainless steel structures, the maximum dimensions: 3000x5000x15000 mm, the maximum structure weight: 20000 kg,

- steel alloy structures welding according to MIG and TIG methods – the maximum dimensions: 3000x5000x15000 mm, the maximum construction weight: 1000 kg,

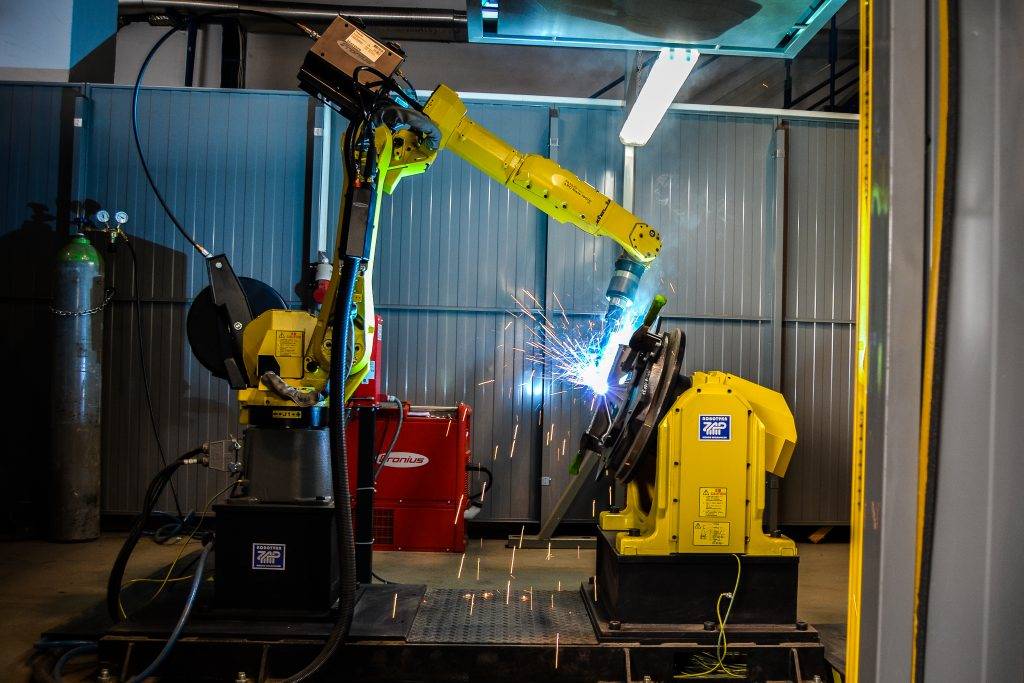

- an automated welding station – an application of the FANUC ARC Mate 100iC/7L – 6-axis robot with

2-axis positioner. It is a gas shielded welding with application of a consumable electrode - blast cleaning – the maximum component dimensions: 1500x2000x1200 mm.

Other industrial services

Vacuum washing

- vacuum washing and solvent cleaning machine – CASTO VACUUM-CAST 3000 – precision washing and detail degreasing of complex geometry structure components, blind holes, high porosity components, components stained with oils, coolants, abrasive compounds which are hard to remove. The cycle of work is hermetic, air-proof, leak-proof and emission free. The process is characterized by a high level of cleanliness. The internal dimensions of the device: 2450x500x450 mm. The maximum charge weight: 250 kg.

Thickness measuring of electroplated coatings according to the X-ray fluorescence spectroscopy method

- Fischerscope X-Ray XDL 230s – testing station built according to DIN 50987, ISO 3497, ASTM B568 standards respectively:

- single, double and triple electroplated coatings measuring,

- composition and thickness testing of binary and three component alloy coatings as well as sublayer and inverse array layer testing,

- alloy composition testing up to 4 alloy components,

- the maximum sample weight: 20 kg,

- internal dimensions of the test chamber: (Height/Width/Length) 140x460x500 mm.

Gallery