Description

Measurement laboratory:

- the lab is responsible for taking length and angular measurements, error shape measurements and roughness measurement,

- validation of control-measuring equipment (e.g. vernier calipers, micrometer gauges etc.).

Chemical laboratory:

- determination of chemical composition according to the spectrometric method,

- measuring the thickness of electroplated coatings according to the X-ray fluorescence spectroscopy method,

- electroplating solution analysis,

- inspection of paints, varnishes, lubricants and oils,

- corrosivity testing and leak-proof testing of protective coatings in salt spray chambers.

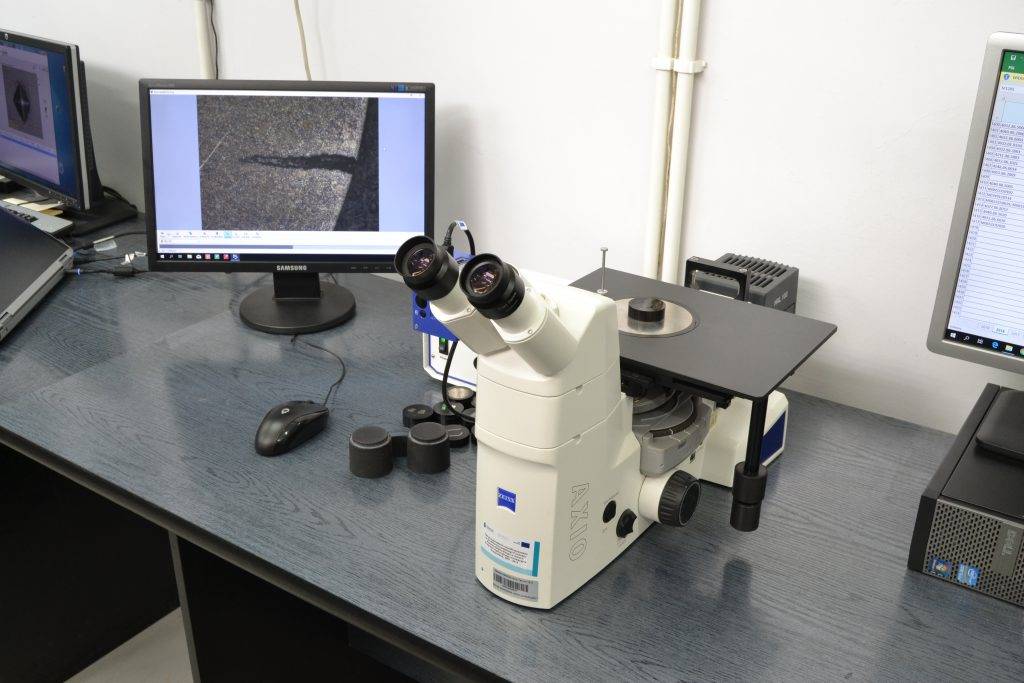

Material strength, metallography and flaw detection testing laboratory:

- hardness testing according to Vickers, Rockwell and Brinell methods,

- material mechanical properties testing: tension testing, impact testing (also in lower temperature),

- hardened coatings thickness testing according to the hardness penetration pattern method,

- microscopic and macroscopic steel examination and its alloy compounds testing,

- nitrided, anodized, galvanic and carburized coatings quality determination,

- nondestructive testing (flaw detection): magnetic and penetration tests,

- the lab is responsible for expertise execution in scope of metal science and heat treatment. We specialize in technical and technological problem solving that occur during manufacturing process. The aforementioned research is conducted according to a set of the following standards: PN, PN-EN, PN-EN, ISO. Laboratory apparatus and measuring equipment are a subject of internal supervision and metrological confirmation by the Regional Verification Office.

Environmental chamber research, vibration and shock resistance testing, impact resistance trials and physical quantity measurements

Environmental chamber testing:

- environmental chamber – type: UC7 = -60/+120, usable area: 8.5 m³ (1.7×2.5×2 m), temperature range: -60÷+120°C, the scope of relative humidity: 10÷95%, range of temperature intervals: 20÷80°C, shooting can be performed from the inside of the chamber,

- rapid temperature changes environmental chamber – type: SU1000 C10 ESS, usable area: 1320 liters (1×1, 2×1, 1 m), temperature range: -70÷+180°C, the scope of relative humidity: 10÷98%, range of temperature intervals: 20÷95°C, rapid temperature changes maximum velocity: 10°C/min.,

- corrosion resistance chamber – type: DCTC 1200P, usable area: 1200 liters (0.7×0.78×1.7 m), temperature range: ambient temperature: ÷+55°C, the chamber is used for material and coating corrosion resistance,

- dust-proof and dust-resistant chamber – type: TPSD 8500, usable area: 8.36 m³ (2×1, 9×2, 2 m), temperature range: ambient temperature: ÷+65°C, shooting can be performed from the inside of the chamber,

- rainwater chamber – type: WD 10000, usable area: 12.48 m³ (1.95×2.0x3.2 m), temperature range: ambient temperature: ÷+80°C, 20 spray nozzles/jets including: 4 vertical nozzles,

8 horizontal nozzles and 8 angular nozzles, shooting can be performed from the inside of the chamber.

Processes are recorded with camera

Recording camera for registering rapid change occurrences – type: Phantom v. 711, capacity/bandwidth:

7 G pix/s, the maximum recording rate in HD resolution (1280×800 pix.) equals: 7530 frames per second, the maximum resolution 128×8 pix.

Object testing with the DONGLING ES-30-370 vibration system using GT800 slide table

The system operates on 3-axis mechanism in simple harmonic motion and stochastic motion, the applied force is equal to 30kN and in impact movement the value is equal to 60kN. The maximum acceleration equals 100 g, vibration amplitude: 25.4 mm. Static load capacity equals 500 kg.